~Interest rates range from 7% p.a. – 12.29% p.a.. (Comparison rates range from 7.9% p.a. – 13.61% p.a.^). The actual interest rate will depend on the borrower’s circumstances and financial situation.

~ Comparison rate is calculated on a secured consumer fixed rate loan of $30,000 for a term of 5 years. WARNING: This comparison rate is true only for the examples given and may not include all fees and charges. Different terms, fees or other loan amounts might result in a different comparison rate.

Information provided is factual information only and is not intended to imply any recommendation about any financial product(s) or constitute tax advice. If you require advice, you should consult a licensed financial or tax adviser.

All applications are subject to lender assessment, eligibility criteria and lending limits. Terms, conditions, fees and charges apply. Stratton Finance Pty Ltd Australian Credit Licence No.364340, AFCA Member, and FBAA Member. Suzuki Australia Pty Ltd is a trademark of Suzuki (ABN 57 001 828 164). Credit provided by BOQ Credit Pty Ltd ABN 92 080 151 266 Australian Credit Licence 393331.

Suzuki Marine may receive a financial benefit for referrals that result in a settled loan with one of Stratton Finance’s panel of lenders.

Personal information is collected, used, stored and disclosed in accordance with Stratton Finance’s Privacy Policy and Suzuki Finance’s Privacy Policy.

*‘Sail Away’ on 2.5 to 30hp tiller-controlled models the price includes dealer pre-delivery charges. Tiller models 40HP and above excludes pre-delivery costs.

“Manufacturer’s Suggested Retail Price” (MSRP) excludes fitting and associated costs.

CLEAN UP THE WORLD CAMPAIGNClean-Up the World Campaign is the root of Suzuki’s awareness to environmental issues and the SUZUKI CLEAN OCEAN PROJECT. Since 2010, Suzuki Motor Corporation has been voluntarily conducting the ‘Clean-up the World Campaign’ essentially a collection of organised clean-up activities in seas, rivers, lakes, and ponds where the outboard motors are used. This event is conducted annually to contribute to a healthier and cleaner marine environment. Over 10,000 people & 44 distributors have participated in this global initiative so far. Suzuki is committed to taking responsible actions against plastic waste problems by reviewing its own contributions to the environment and introducing new measures to reduce plastic usage and waste. |

|

|

REDUCE PLASTIC PACKAGINGTo reduce plastic waste, Suzuki has acted towards reducing the plastic packaging of Suzuki outboard motor products. Alternative eco-friendly packaging materials have been adopted to some products manufactured after June 2020. Suzuki Motor Corporation strives to continually minimise the use of plastic packaging in both its current and future products. |

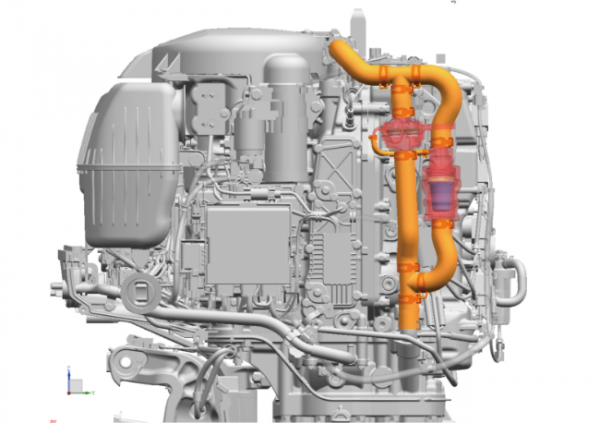

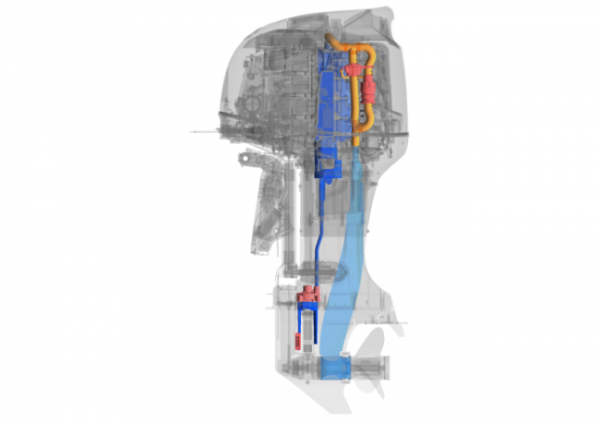

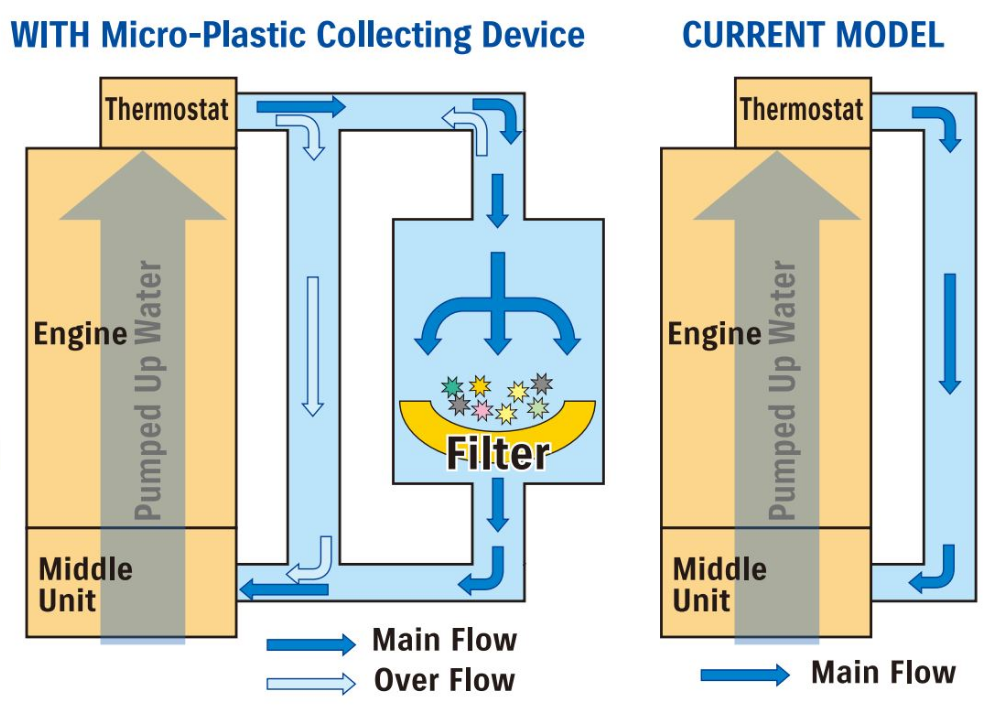

COLLECTING MARINE MICRO-PLASTIC WASTEMarine plastic waste has been a significant environmental issue for many years. More recently, secondary microplastics (small plastic fragments) have become of increasing concern. |

|

|

|

This design has no negative impacts on engine performance in any way since only returning water that has already been used to cool the engine is used. There is also a secondary bypass hose that maintains water flow in the event the filter ever become clogged.

The device has been tested in over 15 different countries, including Australia. Upon analysis, all samples provided from around the glove showed evidence of micro-plastics. Materials collected include acrylic, cellophane, epoxy, nylon, PET, polypropylene, polyethylene, urethane, and vinyl ester.

|

|